Protection Wrap Film Product Specification

ARRIVE IN STYLE

I. Product Description

Protection Wrap Film, also known as Color PPF, utilizes thermoplastic polyurethane (TPU) as its base material,

infused with chromatic materials. Manufactured through coating and laminating processes, it achieves dynamic

color-shifting properties while maintaining high elasticity, abrasion resistance, and weather-ability. The film

features exceptional scratch/scrape resistance, oxidation resistance, and self-healing capabilities. It delivers

superior color saturation and gloss compared to conventional films and finds extensive applications across

diverse industries. This product integrates color transformation with paint protection film (PPF) functionality

innovatively.

II. Key Features

High Toughness & Abrasion Resistance: The TPU material offers superior tensile strength and tear resistance,

effectively shielding surfaces from physical damage like everyday scrapes and road debris impact.

Self-Healing Properties: A specialized surface coating incorporates elastic memory polymers. Minor surface

scratches self-repair through molecular realignment when exposed to moderate heat (e.g., sunlight or warm

water).

Premium Color Performance: Available in a wide spectrum of colors with options for custom color matching to

meet specific client requirements.

III. Applications

This versatile film is engineered for use across multiple sectors, including:

•

Automotive Industry (Vehicle wraps, PPF, decorative trim)

•

Consumer Electronics & Wearable Tech (Device casings, protective covers)

•

Architectural & Design Surfaces (Interior/exterior accents, signage)

•

Industrial Packaging & Specialty Surfaces

IV. Product Image

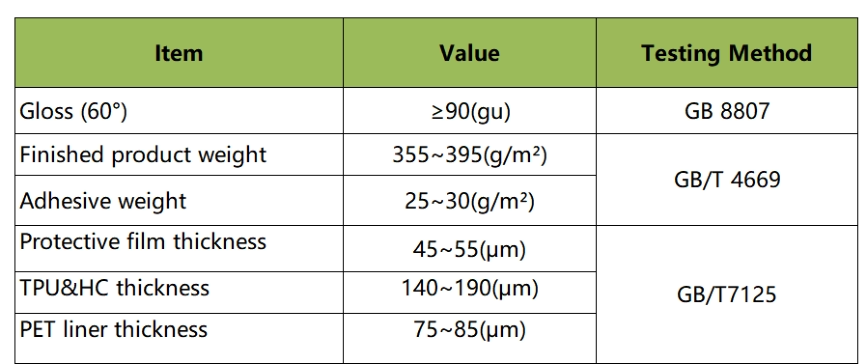

Specification

V. Product Typical Structure

The typical structure of a finished color-change film includes: protective film, coating layer, TPU transparent film,

colored polyurethane layer, polyurethane layer, pressure-sensitive adhesive, and release liner.

Protective Film / 保护膜 (50u, Self-developed)

Coating Layer / 涂层 (7u)

TPU Transparent Film / TPU 透明膜 (115u)

Colored Polyurethane Coating / 聚氨酯色层 (20u, Self-developed)

Polyurethane Substrate / 聚氨酯底层 (20u, Self-developed)

Pressure-sensitive Adhesive / 压敏胶 (28u)

Liner / 离型膜 (75u)

VI. Technical Standards

Appearance Standards

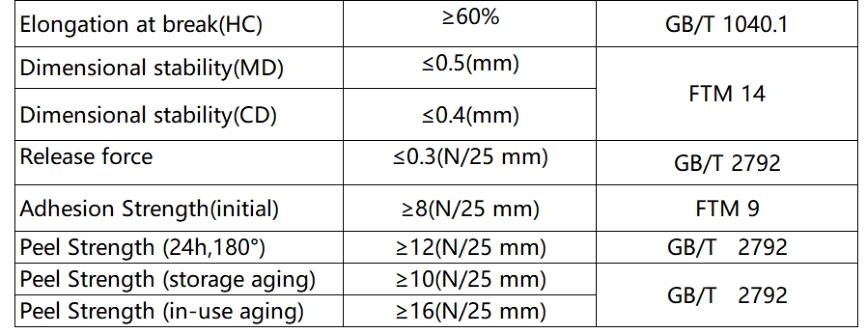

Physical Indicators

Testing Method Description:

•

HC Protective Film Elongation at Break: Refers to the elongation value recorded when the HC coating fractures

during tensile testing of the finished product, conducted in accordance with GB/T1040.1 Plastics—Determination

of tensile properties—Part 1: General principles.

•

Aged Peel Strength (Storage Condition): Indicates the 180° peel strength measured per GB/T2792 after the

sample undergoes 65°C/72h aging treatment.

•

Aged Peel Strength (Application Condition): Indicates the 180° peel strength tested after the adhered sample

undergoes 65°C/72h aging treatment and subsequent cooling to ambient temperature.

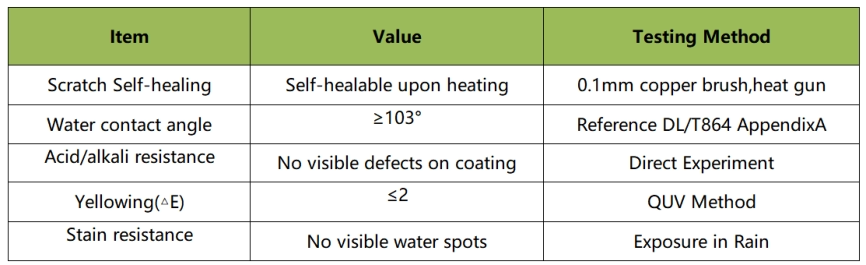

Functional Data

Testing Method Description:

•

Self-healing Performance: After performing 10 circular scrubbing cycles on the coating surface using a brass

brush with wire diameter ≤ 0.1mm, visually inspect the disappearance of fine scratches after heating with a

heat gun or 100°C boiling water.

•

Acid/Alkali Resistance: Apply 10 vol% hydrochloric acid and 0.1 mol/L sodium hydroxide solution to the sample

surface. After natural exposure for 24 hours, evaluate the sample for absence of visually detectable coating

defects (e.g., bubbles, cracks).

•

Stain Resistance: Subject the sample to accelerated degradation using equipment with UV radiation, heating,

and spraying functions. Parameter settings shall comply with relevant provisions of GB/T16422.2, with general

industrial water used for spraying.

Feel free to call us in working hours Mon - fri

9:00am - 6.00pm. Our team will be happy to

help answer your queries

+60 11-1618 8008

Company

Help

Work Hours

Home

Specification

TPU Color PPF Series

PET Vinyl Series

Contact Us

Sucesss Case

Terms & Condition

Privacy Policy

9 AM - 6 PM, Monday - Saturday

support@wtbfilm.com

No.17, Jalan STR 2 Saujuna

Teknologi 48000 Rawang

Selangor

Copyright © 202025 WTB FILM PREMIUN CAR WRAPPING. All rights reserved.

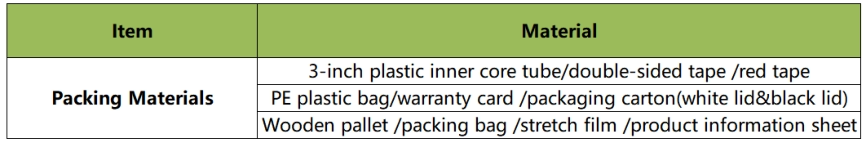

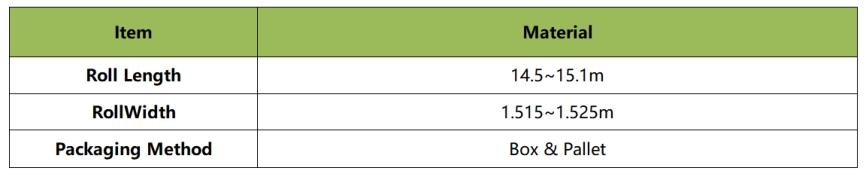

VII. Packaging Standards

Packaging Materials:

Packaging Specification:

Please Note:

The packaging methods and corresponding materials listed are standard specifications only. For special or

additional requirements, the actual shipment shall prevail.

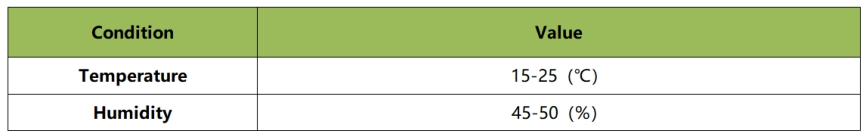

VIII. Storage Conditions

Instructions:

•

All protection wrap films must be stored in their original packaging using the protective materials supplied with

the raw materials.

•

Hermetic storage with vertical stacking is recommended as the optimal solution. Avoid direct sunlight exposure

and contact with heat sources.

•

After unpacking, residual materials must have their high-definition protective film layers promptly removed to

prevent storage defects such as edge warping and surface blushing.

•

Strict adherence to warehouse temperature and humidity control requirements is essential for maintaining

product performance and effectively preventing environmental degradation.

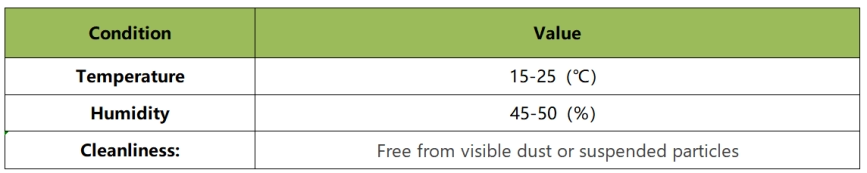

IX. Installation Conditions

Instructions:

•

All protection wrap films must undergo die-cutting or plotting operations in controlled environments to prevent

adverse temperature and electrostatic conditions from compromising product appearance and performance.

•

Strict surface preparation of automotive paint must be performed prior to installation, eliminating residual

particles and oil contaminants that may cause application defects.

•

Car washing must be avoided for one week post-installation, and prolonged rainwater exposure prevented,

ensuring optimal wetting of the adhesive to achieve maximum bond strength.

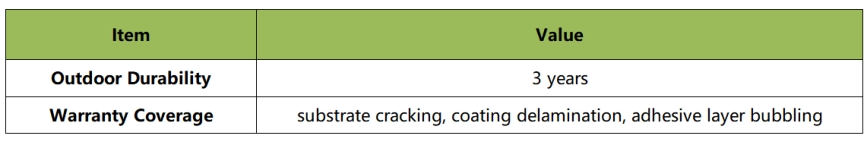

X. Durability & Warranty

Instructions:

•

The weatherability of all protection wrap films must meet specified storage conditions and standardized

installation procedures throughout their service life.

•

For defects covered by the warranty, strict adherence to product use and maintenance protocols is mandatory.

Detailed specifications are provided on the pack-in identification card and official statement included with the

product.

READY TO WRAP?

Transform Your Ride,

Your Way

Step into the world of premium car wrapping. At [Your Business Name],

your perfect vehicle makeover is just a few clicks away — stylish designs,

professional installation, and protection, all at your fingertips.

Browse Our Wraps